Ethylene / Ethane Terminal Expansion

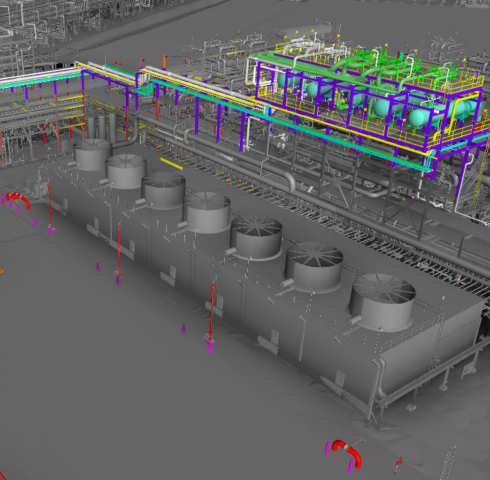

An ethylene export capacity expansion project on the Texas Gulf Coast, adding a new flex train to an existing terminal using repurposed refrigeration systems.

Project Details

OPD provided engineering, procurement and construction services to expand the existing ethylene feed capacity of an ethylene/ethane export terminal on the Texas Gulf Coast. The new ethylene train utilizes existing, spare propylene and ethane refrigeration capacity from the site to significantly increase ethylene export capabilities. This brownfield project had extensive tie-ins to both existing ethylene and ethane trains with major modifications to existing structures/foundations to support new equipment. The new ethylene train is a flex unit designed with the capability to manage a high frequency of start-ups throughout the year based on its intermittent usage, which is a particular challenge for wear on rotating equipment.

- Significant increase in ethylene export capabilities

- Existing refrigeration capacity repurposed for use on existing ethane train, new ethylene flex unit, or dual mode of operations with reduced capacity on both

- Heavily integrated controls logic for differentiation between existing vs. new compression equipment depending on which trains are in operation

- Strategic use of OPD designed and constructed custom process modules to accommodate tight site spacing and laydown area constraints

You may also be interested in

View all featured projects

Propane / Butane Export Terminal

A propane/butane export terminal delivered on the Texas Gulf Coast, designed for 11,000 BPH ship loading and 30,000 HP of refrigeration capacity.

Ethane / Propane Export Terminal

A grassroots ethane and propane export terminal under construction on the Texas Gulf Coast, designed with dual-train flexibility and high-capacity refrigeration.

Natural Gasoline Hydrotreater

A grassroots 60 MBPD natural gasoline hydrotreater delivered on the Texas Gulf Coast, designed to produce ultra-low sulfur naphtha.

Get In Touch

To learn more about how OPD can support your project needs with industry-leading expertise and reliable execution, contact our team today.